A device for concentration of electromagnetic radiation

Impact Focus areas

Research area

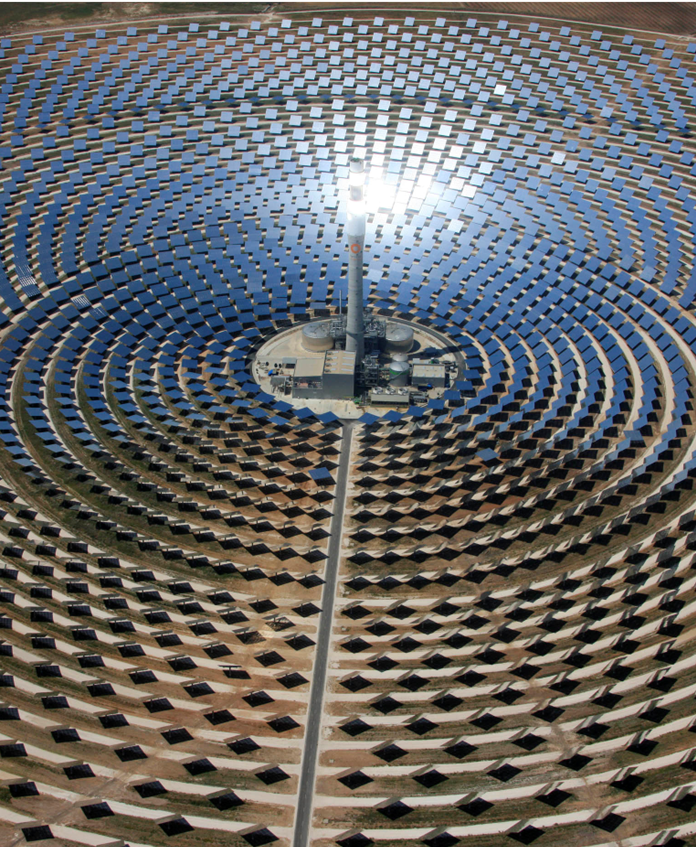

Heliostats concentrate solar radiation reflecting from curved mirror panels spread over a large area of land into a central thermal receiver to provide carbon-free, high-temperature energy which can be used as heat for industrial processes and/or to generate power. Mirror panels need to maintain a highly accurate focus onto the receiver under operational loads from gravity and strong wind conditions to achieve efficient low-cost energy output.

Researchers at The Australian National University (ANU) have developed and prototyped a novel mirror panel support structure that offers a simple, robust and lightweight, and customisable design alternative to current hub-spoke solutions. This backing support structure for heliostat mirror panels increases optical accuracy and decreases material requirements.

Technology (TT2021-005)

The novel panel design improves the optical performance of the mirrors under operational wind and gravity loads, reduces material costs from an optimised design, can be produced accurately at high volumes and low cost using standard sheet forming methods, and is applicable for use in both single and multi-facet heliostats and dishes. Several prototypes have been produced and installed in the field for testing.

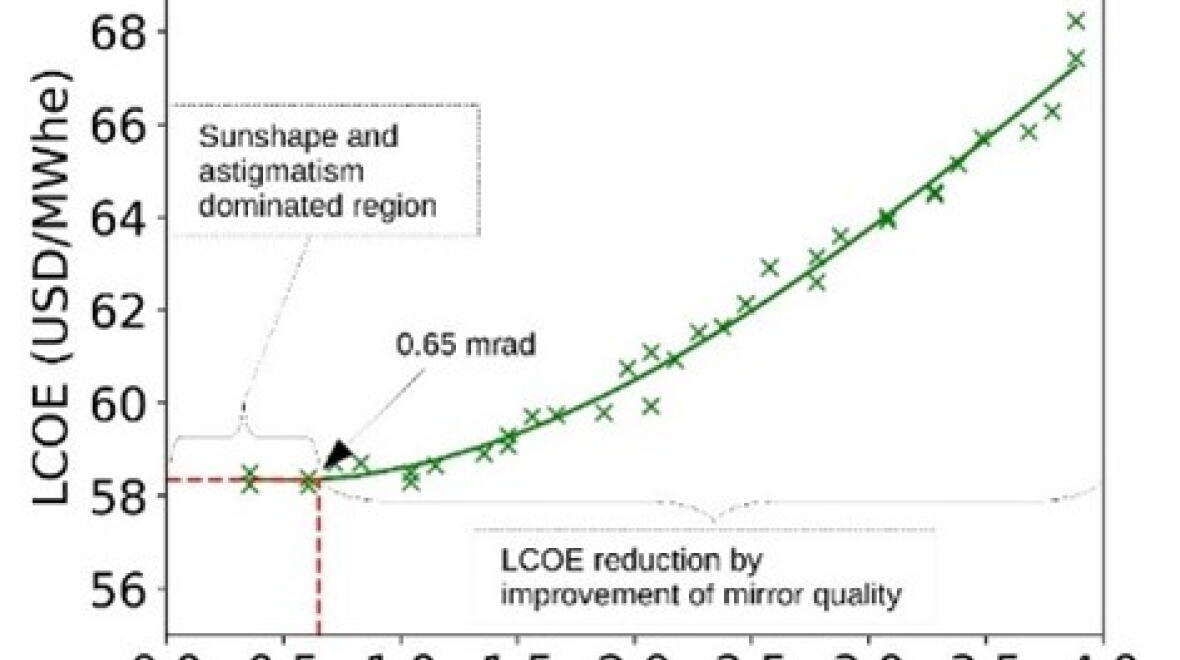

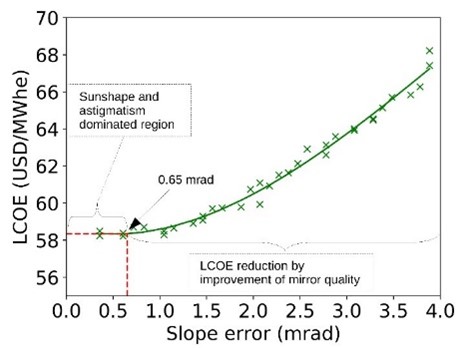

Figure 1: Relationship between optical quality of heliostat (slope mirror) and levelised cost of energy (LCOE)

Potential benefits

- Simple: the panel has only three components: mirror, sheet metal support and adhesive

- Customisable: mirror panel dimensions, focal length and accuracy can be modified to meet application-specific requirements

- Highly accurate: RMS slope error of less than 0.5 mrad is feasible in high volume production.

- Low cost: the panels can be produced using standard sheet forming, automated gluing and assembly

- Durable: designed to minimise corrosion risk by intrinsically ventilated geometry

- Recyclable: the glass and steel in the panels can be recycled at the end of their design life

- Scalable: prototypes up to 2.8 x 1.4 m have been produced at the ANU

- Scale-up flexibility: proven low volume prototyping to de-risk investment in high volume forming processes

- Bankable: same materials and construction methods as used in commercial Concentrated Solar Thermal (CST) fields

Potential applications

- High-efficiency CST plants (heliostats, dishes)

- Single- or multi-facet heliostats

- Adjacent market possibilities

Opportunity

IP status

Key research team

- Dr Joe Coventry, Associate Professor, ANU School of Engineering, Program and Project Leader — The Australian Solar Thermal Research Institute

- Mr Roelof Pottas, Senior Research Officer, ANU School of Engineering

- Mr Johannes Pottas, Senior Research Officer, ANU School of Engineering

Contacts